Some of the country’s largest retreaders are finding ways to convince fleets to add retreads to their tire programs.

A tactic that Noah Hickman, president of Oak Hill, Ohio-based H&H Industries Inc., uses is informing customers of the cost differences between retreaded tires and new tires.

He also educates customers about “ultimate cost-per-hour” and the value of “supporting American-owned businesses.”

David Mickelson, president and CEO of Graham Tire Co., which is based in Sioux Falls, S.D., agrees that highlighting the price and quality of retreads versus new tires helps customers immensely.

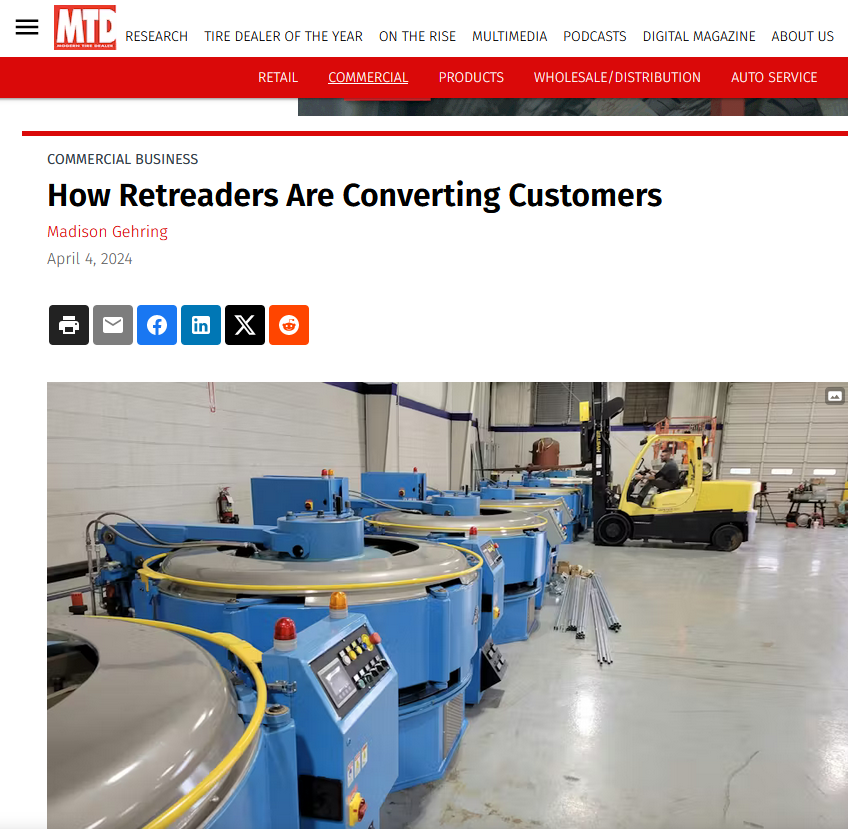

Bob Feldbauer, president and CEO of Logan, Utah-based Jack’s Tire & Oil Management Co., brings fleet customers in for retread plant tours.

“We are proud to have a customer visit our plant unannounced and give them a tour on the spot,” he says.

Bruce Chamblee, chief operating officer at Dorsey Tire Co. Inc., which has locations in Georgia and South Carolina, says building trust with the customer is key.

“This has been a major issue for smaller fleets as their perception is that the only value proposition (of retreading) is cost savings.

“The tire industry, as a whole, needs to do a better job in educating and debunking these myths with customers.”

“There are a lot of rumors that are around that the quality of a retread is not on a par with new tires and that they wear quicker,” says Jon Langerak, president and CEO of Byron Center, Mich.-based Wonderland Tire Co.

Langerak was named MTD’s Tire Dealer of the Year in 2023.

“The easiest and most effective way to show the customer the quality of a retread is to offer to test them in their fleet so they can see for themselves,” he says.

Steve Bobovnik, director of corporate operation at Mulberry, Fla.-based Conlan Tire LC, says he combats these concerns by “getting our product into the fleet for testing.”

Daniel Horn, vice president of sales at Wilkes-Barre, Pa.-based McCarthy Tire Service Co. Inc., emphasizes that “not all retreads are created equal.

McCarthy Tire is a Bandag retreader.

“We also explain the Bandag process,” he says, detailing “the thorough (casing) inspections conducted, including the bead-to-bead casing integrity check, which ensures only suitable casings undergo retreading.